Challenges

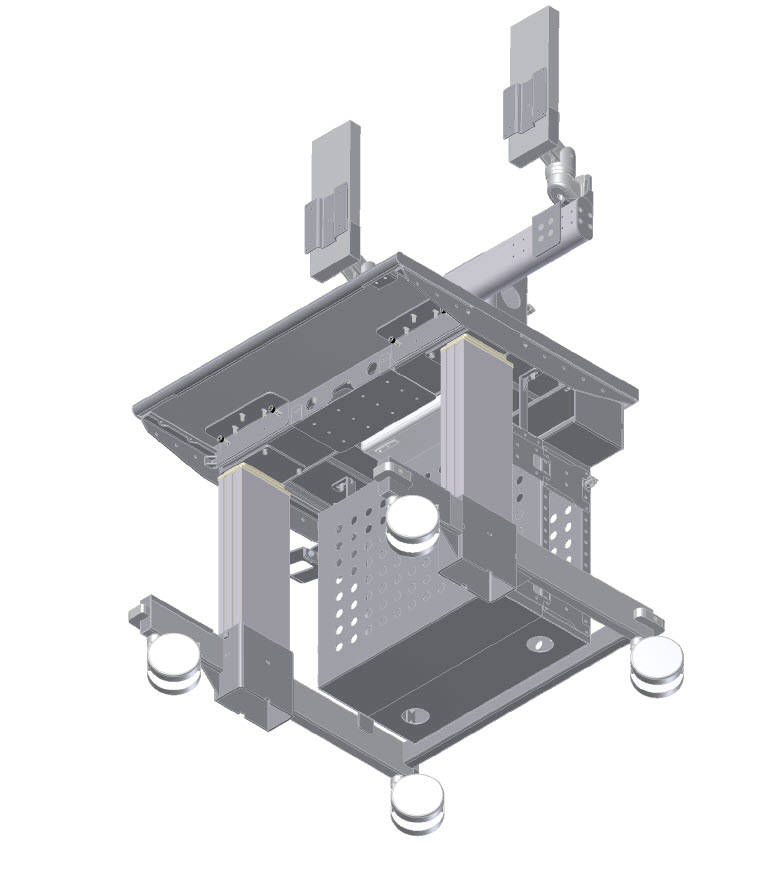

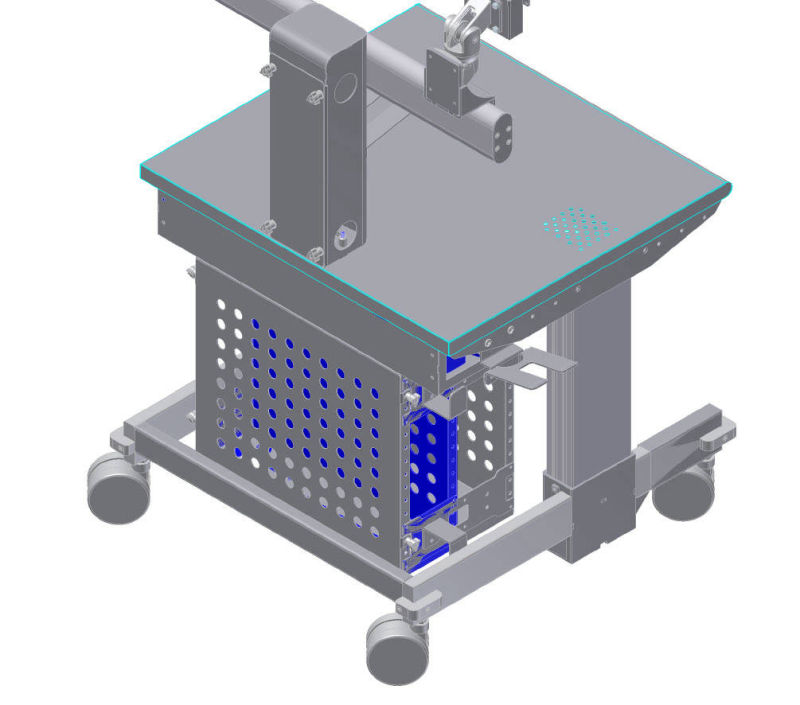

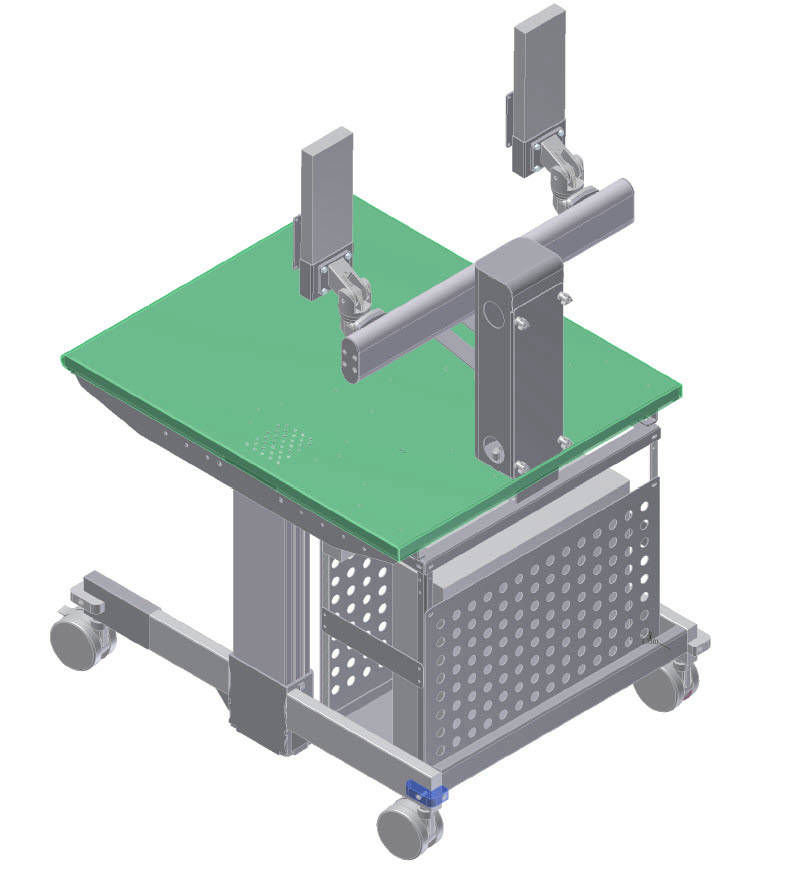

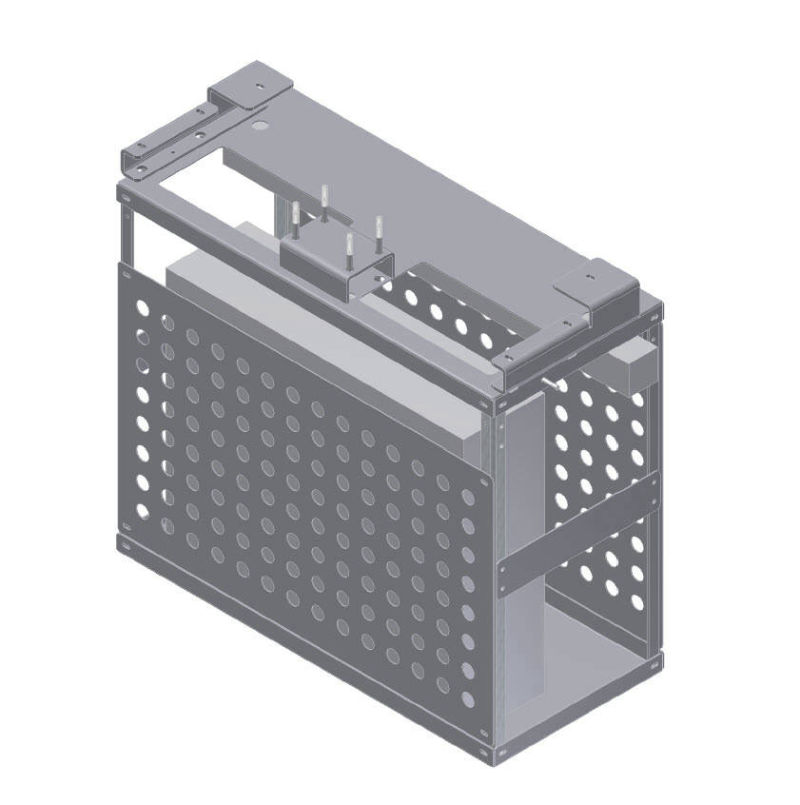

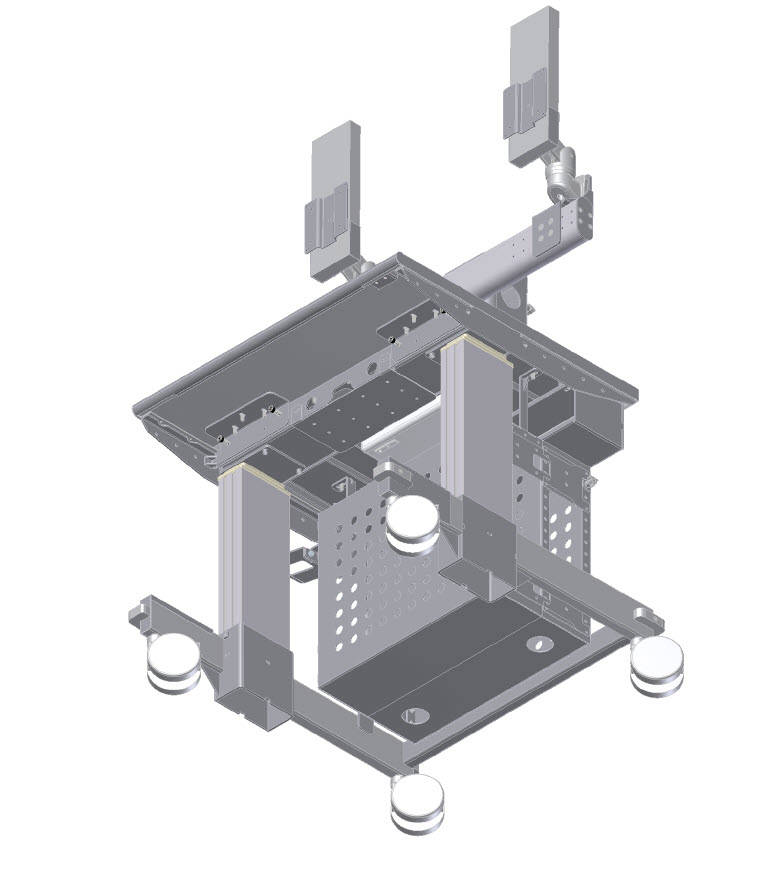

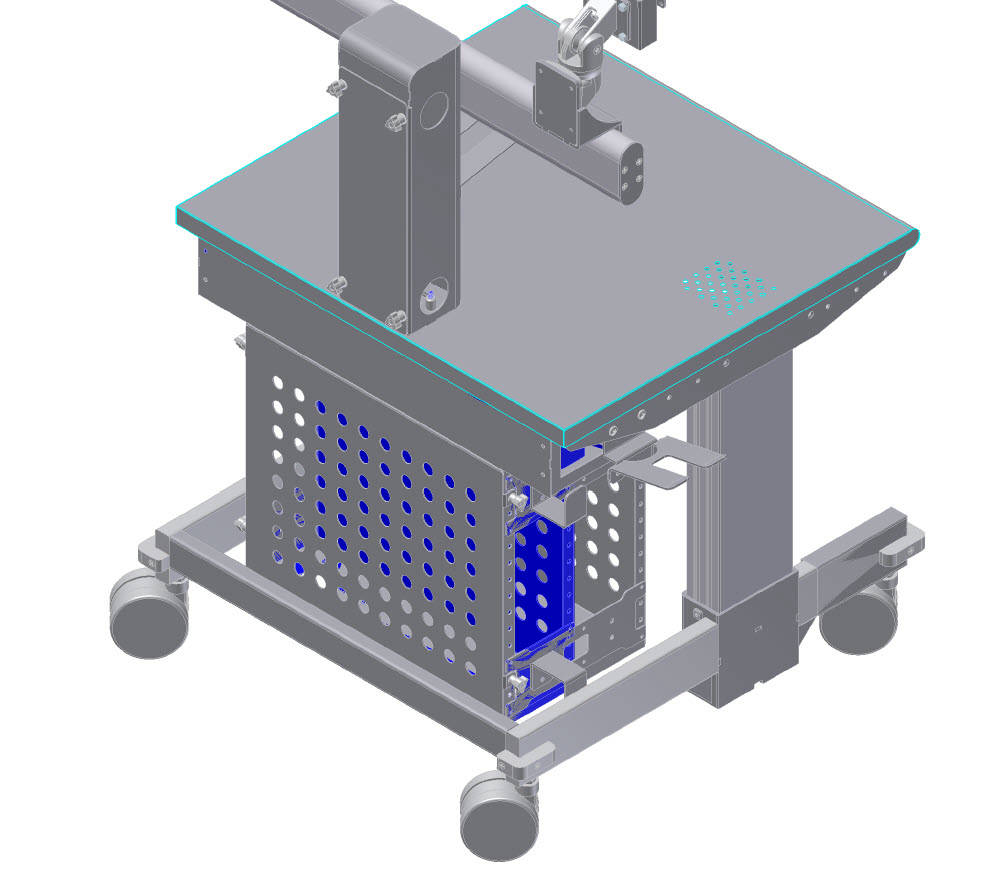

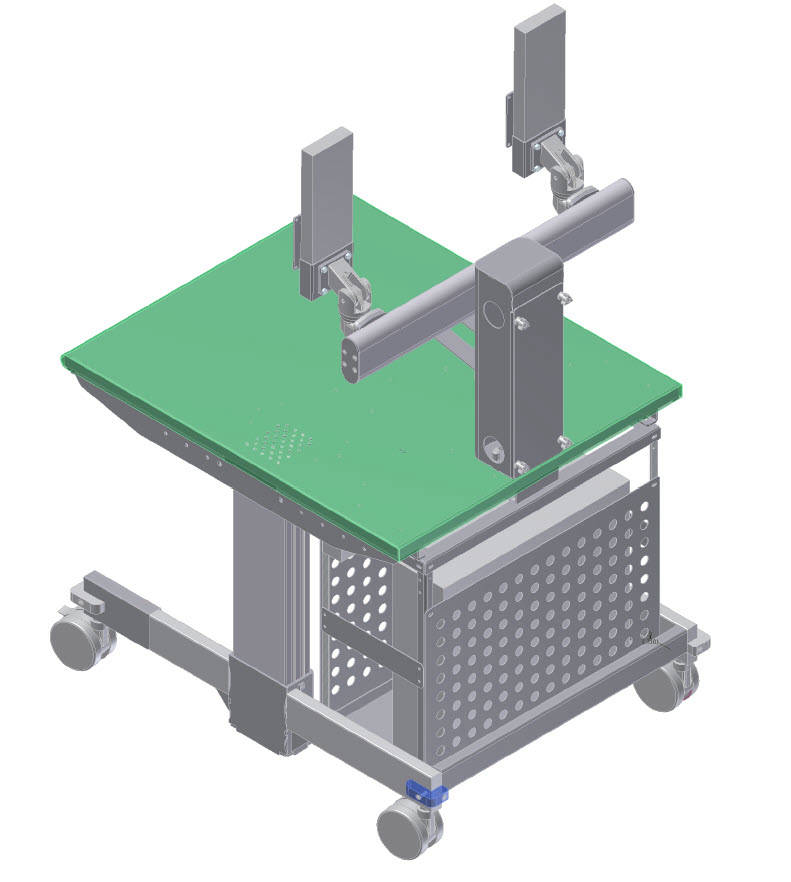

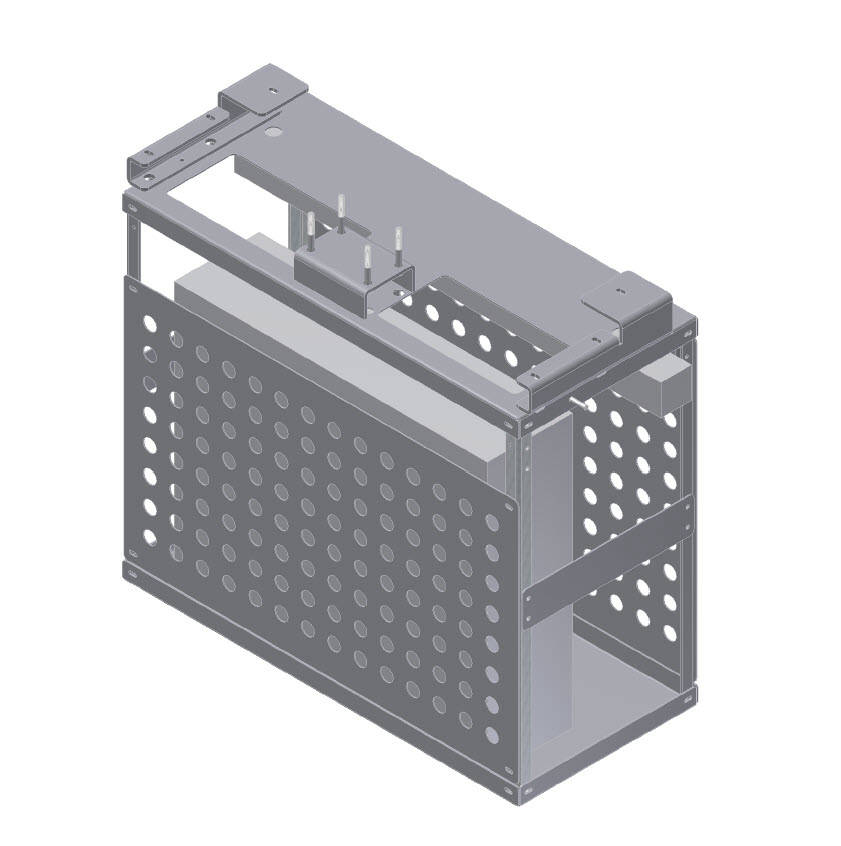

Designing a height-adjustable moving surface that holds most of the weight of the equipment while not generating enough particles to contaminate the clean room environment. This requires some notable adjustments to how the unit is held together and the type of material used in the linear actuators.

Solutions

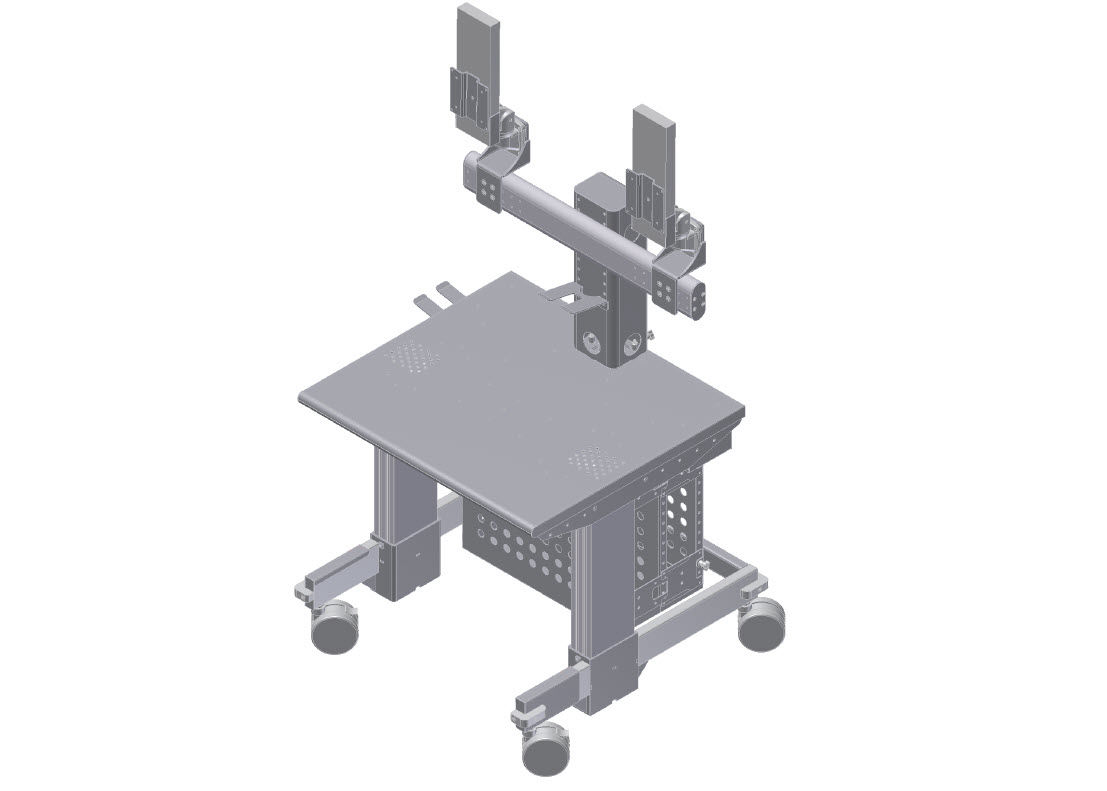

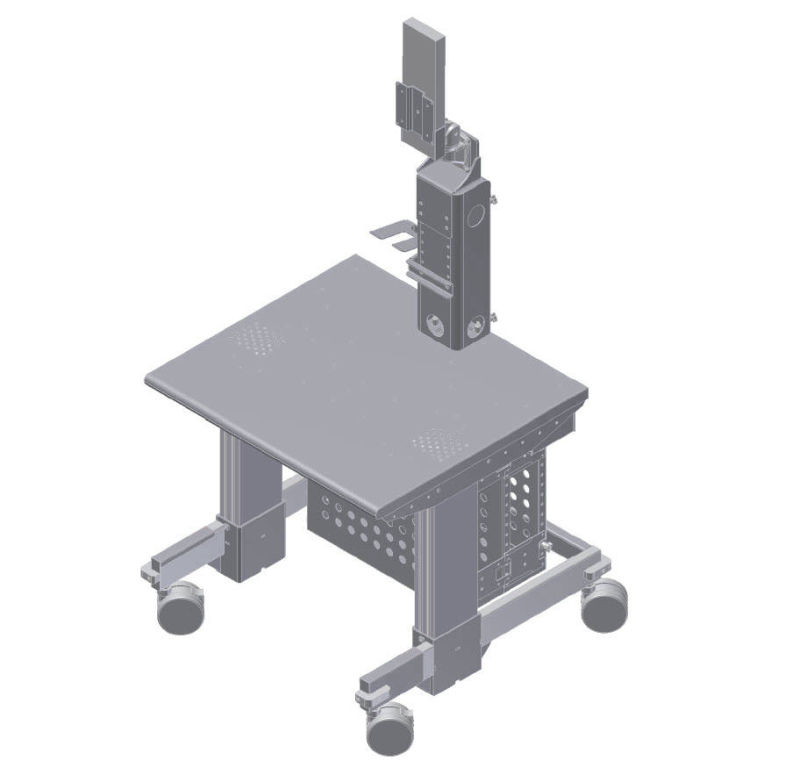

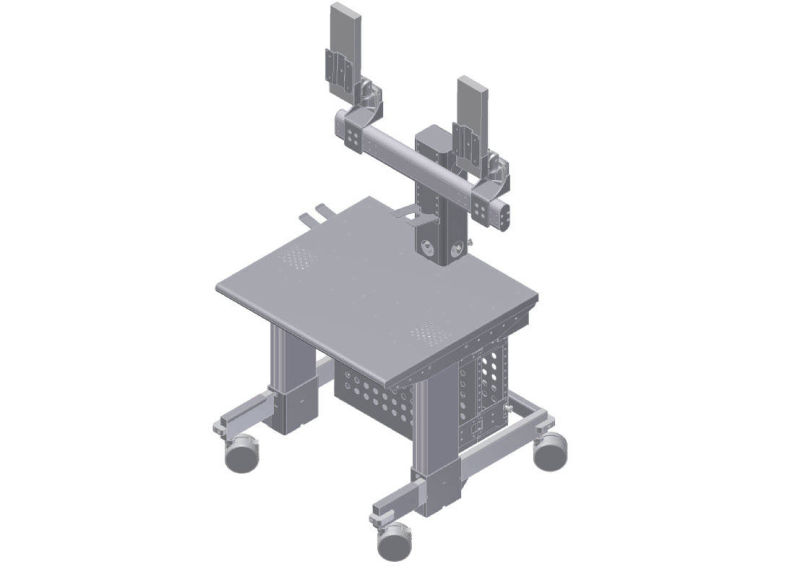

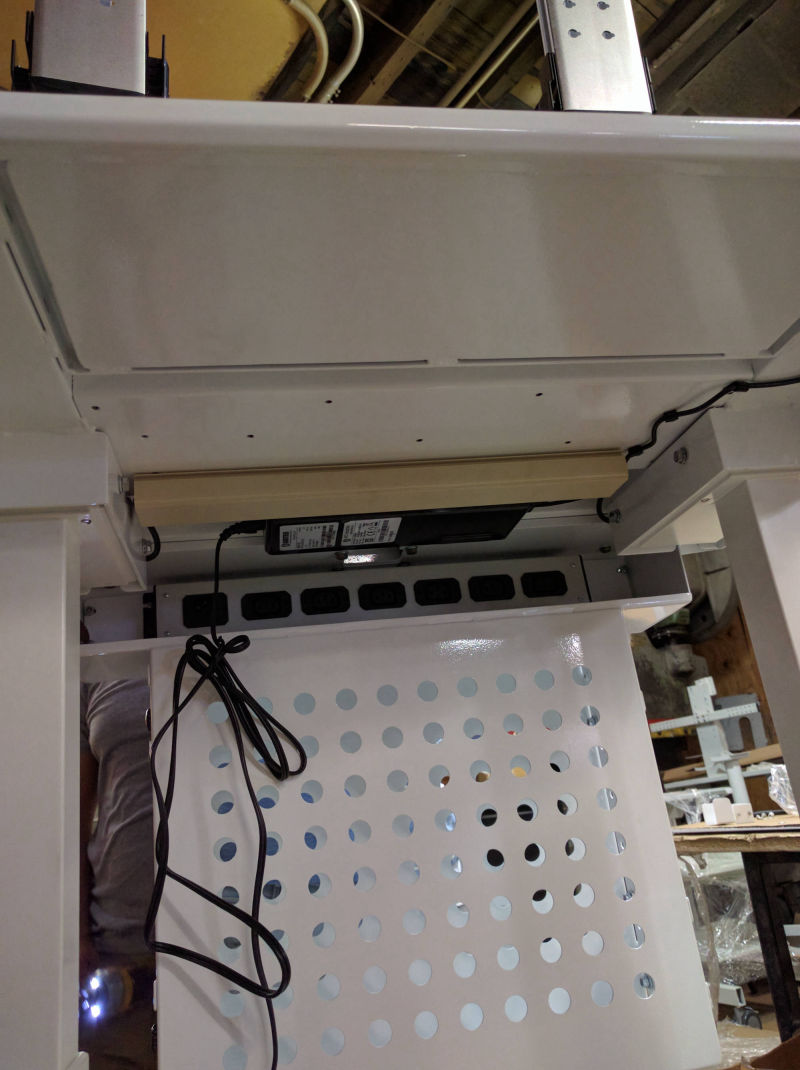

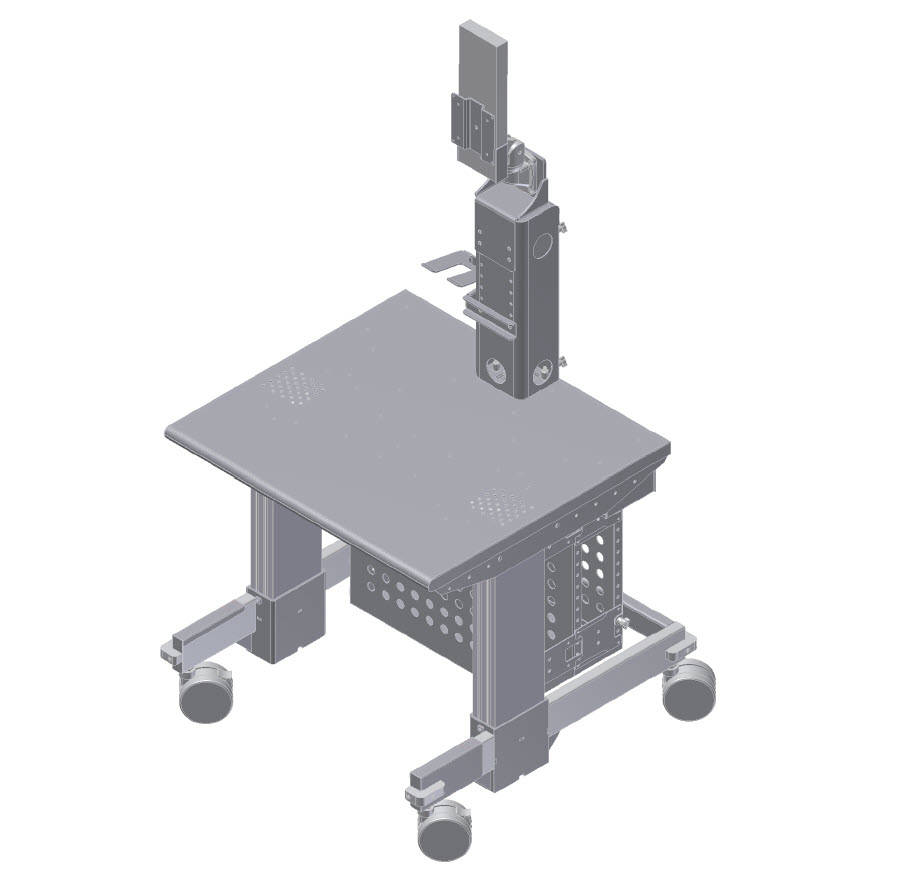

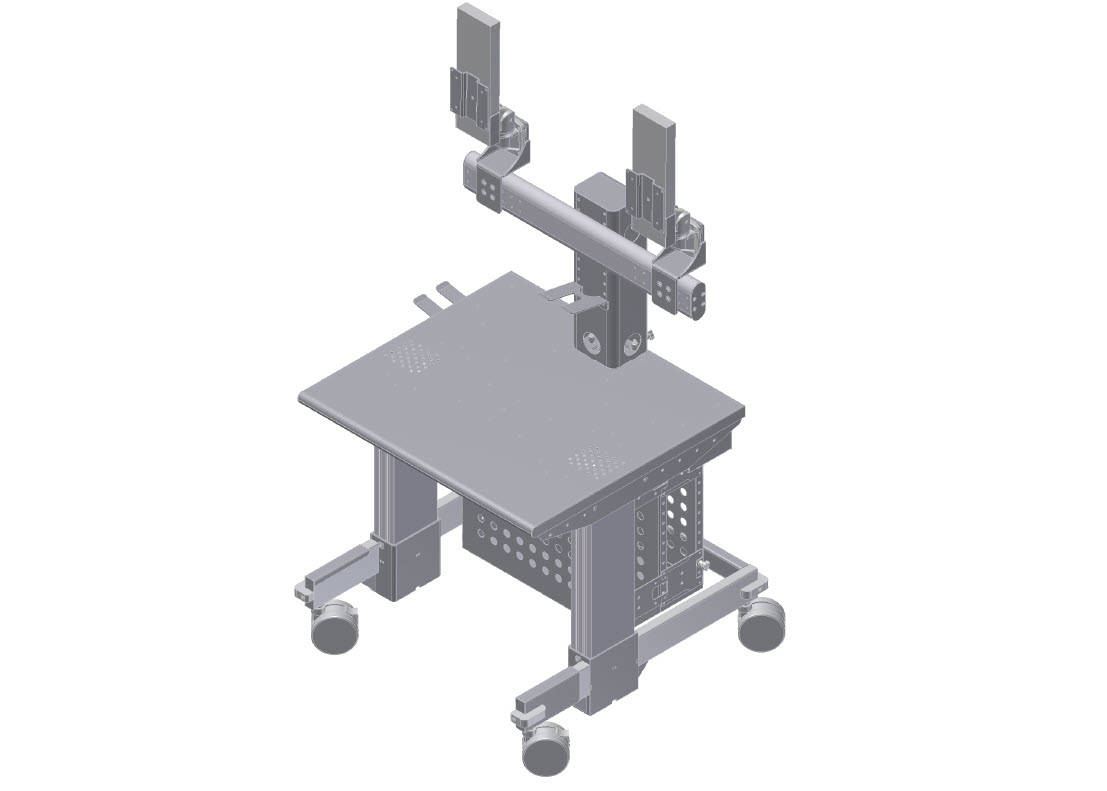

The unit was designed to avoid welding large sheets together as this can correct a space between sheet metal which is a spot for potential corrosion in the cleaning process. All hardware had to be corrosive resistant because of the cleaning process. Also, the hardware had to avoid generating particles during the assembly and usage (like knobs for easy access to the CPU). The linear actuator was designed to avoid using as much lubricant as possible, as the excess lubricant can be a potential contaminant. And the inside of the leg was custom designed to reduce the frictional wear on the parts. The top surface was covered with marine-grade stainless steel so that harsh chemicals could be used on the top surface without issue. The linear actuators had openings designed into the frame so that any particle from manufacturing and even usage can be flushed out before going into the clean room. The unit was also designed to be modular so that different configurations could be delivered easily.